Stancor - manufacturer of Copper Nickel pipes, renowned for their exceptional corrosion resistance, durability, and performance in harsh environments. Ideal for marine engineering, offshore oil & gas, desalination, and shipbuilding, these pipes resist seawater corrosion, biofouling, and erosion, ensuring long-term reliability.

We offer premium grades like 90/10 and 70/30, known for high thermal conductivity, mechanical strength, and stress corrosion resistance, making them perfect for heat exchangers, condensers, and seawater systems. Our precision-engineered Copper Nickel pipes meet ASTM, ASME, and EN standards, undergoing rigorous quality testing to ensure superior performance.

Committed to sustainability and efficiency, Stancor delivers customized solutions for diverse industrial needs, providing high-quality, eco-friendly Copper Nickel pipes designed for long-lasting and efficient operations.

Product Size And Specifications

Products

Size & Range

Thickness

Specification

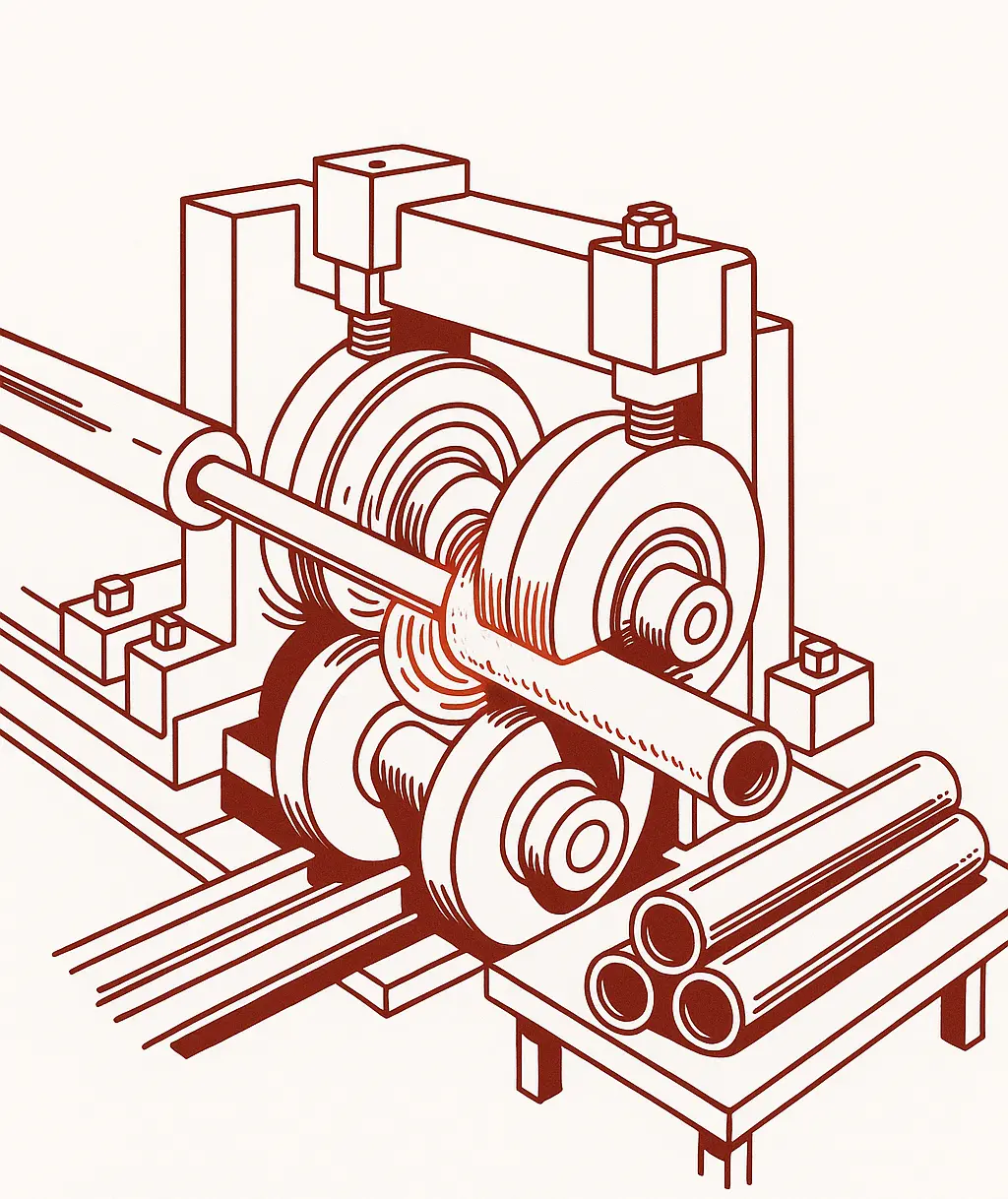

Copper Nickel Pipes

4.76 mm to 219 mm

0.15 mm to 12 mm

ASTM B466 / ASTM B467 / ASTM B111

(90/10) – C70600 / (70/30) – C71500

Available Grades

• Outstanding corrosion resistance in seawater and brine environments.

• High strength and durability with excellent weldability.

• Low macrofouling rates for extended service life.

• Superior thermal and electrical conductivity.

• Chemical Testing: Spectro Analysis, PMI Testing

• Mechanical Testing: Tensile, Hardness, Flattening & Reverse Flattening Tests

• Corrosion Testing: Salt Spray Test, IGC Test

• Microstructure Testing: Grain Size Analysis

• Impact Testing: Charpy Test

• NDT Testing: Eddy Current (ECT), Radiographic (RT)

• PMI Testing: Composition Verification