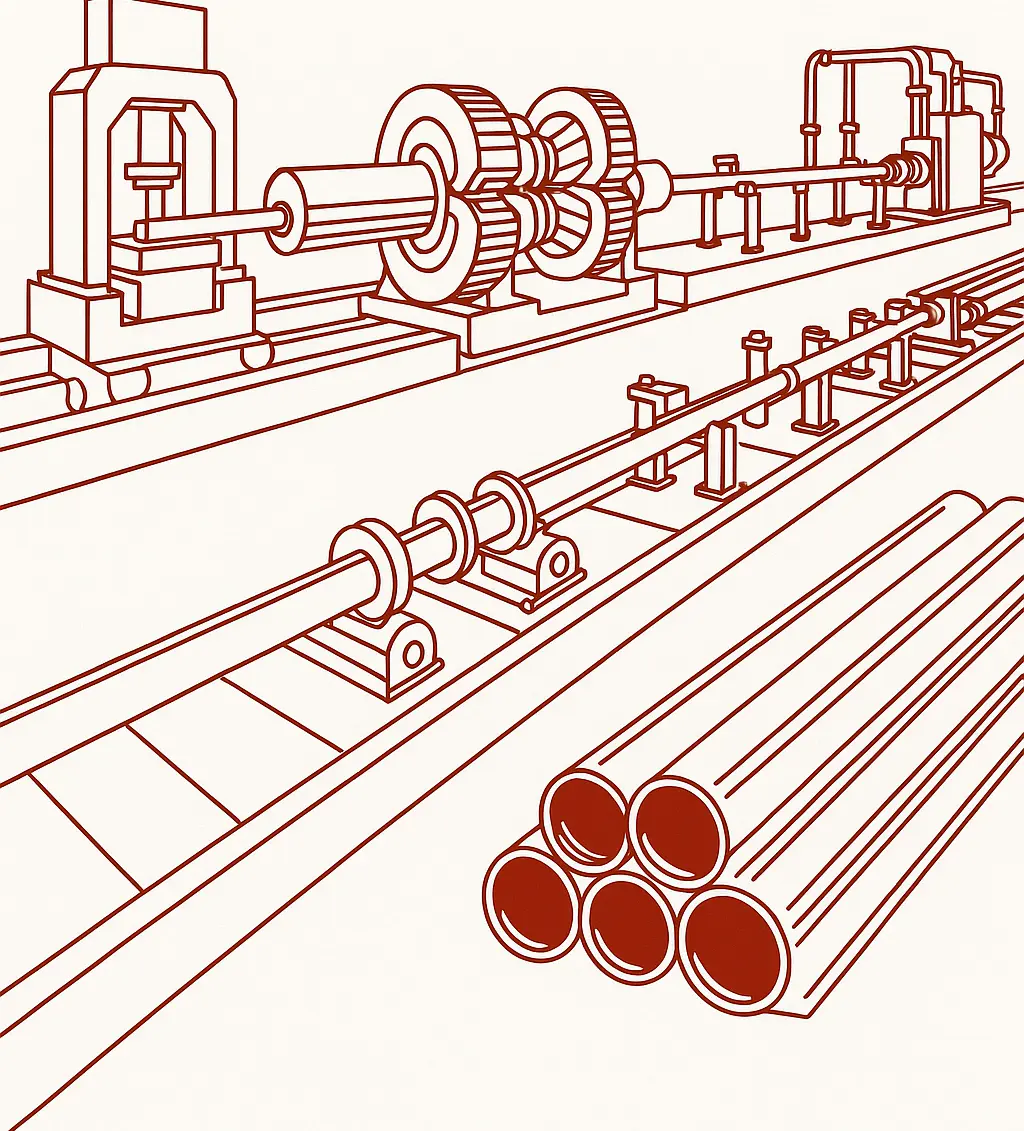

At Stancor Tubular - we specialize in manufacturing high-quality Heat Exchanger Tubes, designed to meet the demanding requirements of industries worldwide. As a piercing-through manufacturer, we ensure superior tube integrity, dimensional accuracy, and long-lasting performance. Our heat exchanger tubes are engineered for efficient thermal transfer, making them ideal for applications in power plants, chemical processing, petrochemical, food & beverage, pharmaceuticals, and marine industries.

Utilizing advanced manufacturing techniques and strict quality control, our tubes are produced with exceptional corrosion resistance, high mechanical strength, and precise tolerances. Available in straight lengths and U-tubes as per customer specifications, our products comply with global industry standards, ensuring reliability in high-temperature and high-pressure environments.

Product Size And Specifications

Products

Size & Range

Thickness

Specification

Heat Exchanger Tubes

10.00 mm to 76.00 mm OD

0.70 mm to 6.00 mm

STM A-213, A-268, A-269, A-270, A-688, A-789, EN 10216-5, SB-163, SB-167, SB-407, SB-423 & SB-444.

TP-304/L/LN/H/N, TP-316/L/LN/H/N/TI, TP-317L, 317LM, TP-321/H, TP-347/H, UNS S31050, S31254, UNS N08904, N08800. N08825, N08020, N08028, TP-405, TP-410, TP-430, TP-446, UNS S31260, S31500, S31803, S32304, S32205, S32750, S32760, UNS N04400, N06600, N06625, N06601 & N010276

Available Grades

• High-Quality Alloys: Stainless steel, duplex, super duplex, and high-performance nickel alloys.

•Custom U-Tubes: Manufactured as per customer drawings for precise fit and performance.

• Global Compliance: ASTM, EN, ASME, JIS, GOST, and AFNOR specifications available.

• Strict Quality Assurance: Ultrasonic testing, hydrostatic testing, and dimensional accuracy checks.

• Chemical Testing: PMI Testing, Spectro Analysis

• Mechanical Testing: Tensile, Hardness (Rockwell/Brinell), Flattening & Reverse Flattening Tests

• Corrosion Testing: IGC Test, Salt Spray Test

• Microstructure Testing: Grain Size Measurement

• Impact Testing: Charpy & Izod Tests

• NDT Testing: Eddy Current (ECT), Radiographic (RT), Ultrasonic (UT)

• PMI Testing: Material Identification & Compliance Verification