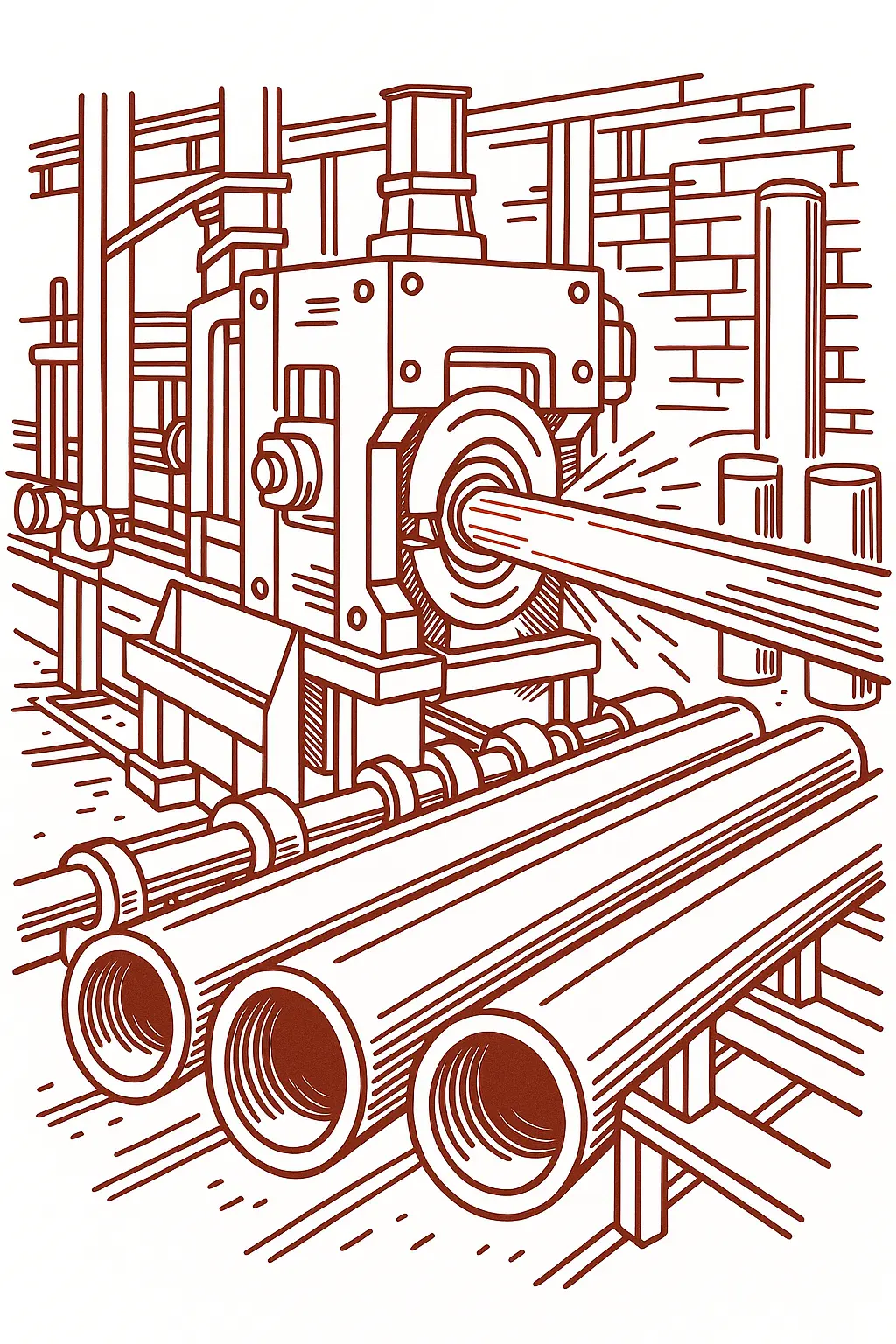

Stancor Tubular - is a trusted manufacturer of high-quality hollow bars, designed for precision, strength, and corrosion resistance across industries such as oil & gas, automotive, construction, marine, and heavy engineering. Our hollow bars feature consistent wall thickness, smooth surfaces, and excellent dimensional accuracy, ensuring superior performance in structural, hydraulic, and mechanical applications.

Manufactured using advanced techniques like hot piercing, machining, and heat treatment, our hollow bars meet stringent quality standards, undergoing ultrasonic testing, dimensional inspection, and material analysis. Available in a wide range of sizes, materials, and finishes, we offer customized solutions to suit diverse industrial needs.

Committed to sustainability and innovation, Stancor employs eco-friendly production methods to deliver high-performance, durable, and responsible manufacturing solutions. Choose Stancor hollow bars for unmatched reliability, efficiency, and excellence in every application.

Product Size And Specifications

Products

Size & Range

Thickness

Specification

Hollow Bars

32mm to 250mm OD

5mm to 30mm

ASTM A-312 & EN 10216-5

TP-304/L/LN/H/N, TP-316/L/LN/H/N/TI, TP-317L, 317LM, TP-321/H, TP-347/H, UNS S31050, S31254, UNS N08904, N08800, N08825, N08020, N08028, TP-405, TP-410, TP-430, TP-446, UNS S31260, S31500, S31803, S32304, S32205, S32750, S32760, UNS N04400, N06600, N06625, N06601&N010276

Available Grades

• High-Performance Alloys – Available in a wide range of stainless steel and specialty grades.

•Customizable Solutions – Sizes, finishes, and specifications tailored to customer needs.

• Rigorous Quality Control – Ultrasonic testing, dimensional inspection, and material composition analysis.

• Eco-Friendly Manufacturing – Commitment to sustainable production and reduced carbon footprint.

• Chemical Testing: Spectro Analysis, PMI Testing

• Mechanical Testing: Tensile, Hardness, Flattening, Reverse Bend Test

• Corrosion Testing: IGC Test

• Microstructure Testing: Grain Size Distribution Analysis

• Impact Testing: Charpy & Izod Impact Tests

• NDT Testing: Ultrasonic (UT), Magnetic Particle (MPI), Radiographic (RT)

• PMI Testing: Alloy Verification & Mix-Up Control