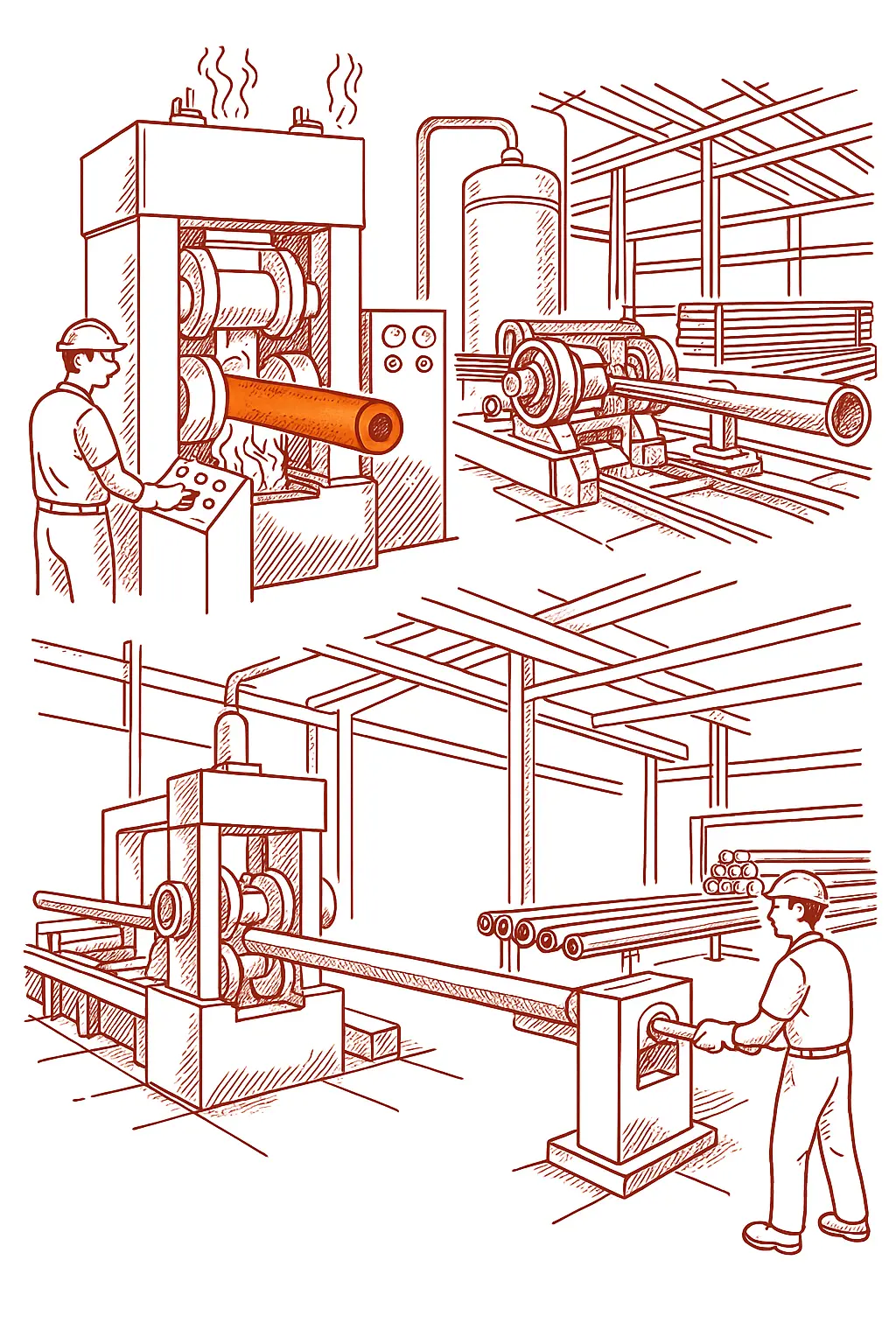

Stancor Tubular specializes in manufacturing Oil Country Tubular Goods (OCTG)—critical seamless pipes used in drilling and production for the oil, gas, and geothermal industries. Our high-performance OCTG range includes drill pipes, casings, and tubing, designed to withstand extreme pressures, corrosive environments, and mechanical stresses.

We offer premium-grade materials, including 22Cr duplex and 25Cr super duplex, widely used in offshore drilling due to their exceptional corrosion resistance, high mechanical strength, and reduced weight requirements. These Corrosion Resistant Alloys (CRA) enhance flow efficiency, lower maintenance costs, and ensure long-term reliability in harsh marine environments.

Our expertise in precision manufacturing and controlled welding techniques, such as Inconel buttering layers, guarantees superior durability and performance, even in deep-sea drilling applications. As offshore exploration advances, Stancor remains committed to delivering high-quality OCTG solutions that enhance safety, efficiency, and well integrity.

Product Size And Specifications

Products

Size & Range

Oil Country Tubular Goods (OCTG)

2.3/8” – 20”

Specification

L80-3%Cr, Super 13C, Duplex 22Cr, Super Duplex 25Cr, Austenitic Alloy, and Nickel Base Alloy

• High tensile strength for deep drilling applications.

•Corrosion and pressure resistance for harsh environments.

• Precision threading for secure and leak-proof connections.

• Available in seamless and welded options.

• Chemical Testing: Spectro Analysis, PMI Testing

• Mechanical Testing: Tensile, Hardness (Rockwell/Brinell), Flattening, Reverse Bend Test

• Corrosion Testing: IGC Test, Sour Service (H2S) Testing

• Microstructure Testing: Grain Structure Analysis

• Impact Testing: Charpy V-Notch Test

• NDT Testing: Ultrasonic (UT), Magnetic Particle (MPI), Radiographic (RT), Eddy Current (ECT)

• PMI Testing: Alloy & Composition Verification