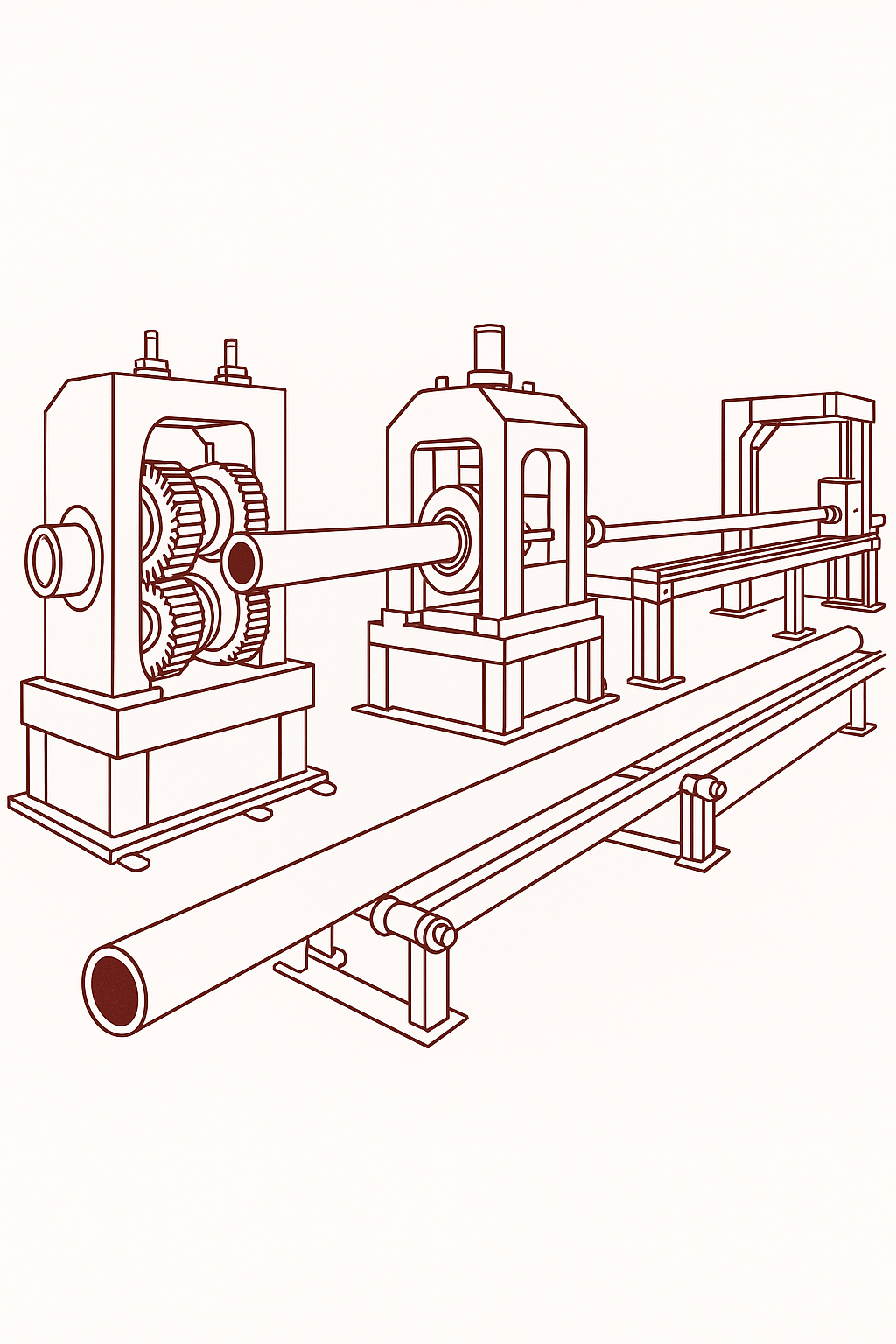

Stancor Tubulars - specializes in manufacturing high-quality Stainless Steel Seamless Pipes, produced using advanced Hot Piercing, Cold Pilgering, and Draw Bench technologies. Our state-of-the-art facility ensures precision, superior surface finish, and strict adherence to international standards.

We offer a wide range of grades, including, Duplex, and Super Duplex, catering to instrumentation, heat exchangers, and critical industrial applications. Our Bright Annealing and Heat Treatment processes enhance mechanical strength and corrosion resistance.

With customized chemistry, dimensions, and tolerances, we provide tailored solutions to meet diverse industry needs. Choose Stancor for reliable, high-performance seamless stainless steel piping solutions.

Product Size And Specifications

Products

Size & Range

Thickness

Specification

Stainless Steel Seamless Pipe

1/8 NPS to 8 NPS

100,000Sch. 5s to Sch. 160

ASTM A-312, ASTM A-376, ASTM A-790, SB-167, SB-407, SB-423, and SB-444

TP-304/L/LN/H/N, TP-316/L/LN/H/N/TI, TP-317L, 317LM, TP-321/H, TP-347/H, UNS S31050, S31254, UNS N08904, N08800, N08825, N08020, N08028, TP-405, TP-410, TP-430, TP-446, UNS S31260, S31500, S31803, S32304, S32205, S32750, S32760, UNS N04400, N06600, N06625, N06601&N010276

Available Grades

• Superior Strength & Durability – Our pipes are manufactured through advanced piercing and extrusion processes, ensuring high mechanical strength and longevity.

•Corrosion & Heat Resistance – Ideal for harsh environments, including chemical processing, offshore drilling, and high-temperature applications.

• Precision Engineering – We maintain stringent quality control to meet international standards and client specifications.

• Custom Solutions – Available in various sizes, thicknesses, and grades to suit diverse industrial needs.

• Chemical Testing: Spectro Analysis, PMI Testing (NABL-Approved Labs)

• Mechanical Testing: Tensile, Hardness (Rockwell/Brinell), Flaring, Flanging, Flattening, Reverse Bend Test

• Corrosion Testing: Intergranular Corrosion (IGC) Test (A, B, C, E methods)

• Microstructure Testing: Grain Size Analysis (Jeffries Method)

• Impact Testing: Charpy & Izod Tests

• NDT Testing: Ultrasonic (UT), Radiographic (RT), Magnetic