At Stancor Tubulars, we specialize in manufacturing high-quality Stainless Steel Instrumentation Tubes designed for precision applications in industries such as oil & gas, chemical processing, power plants, and hydraulics. These tubes are known for their exceptional corrosion resistance, high pressure tolerance, and dimensional accuracy, making them ideal for fluid and gas control systems.

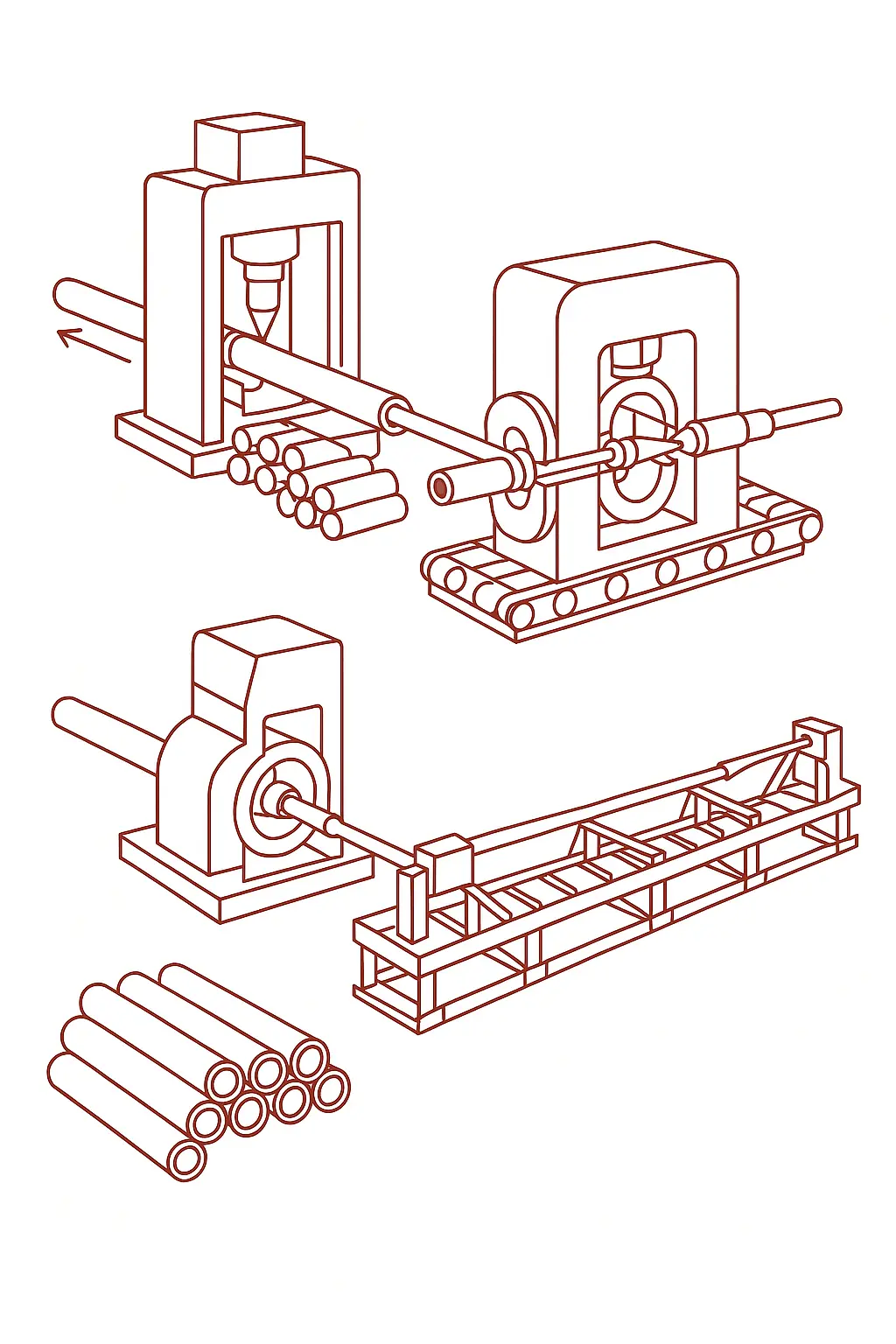

Our state-of-the-art manufacturing process ensures superior quality and precision: Piercing Process – Using a Hot Piercing Mill, stainless steel billets are converted into seamless mother hollows with precise tolerances. Cold Pilgering & Drawing – The mother hollows are further refined using Cold Pilger Mills and Draw Benches to achieve the desired dimensions and surface finish. Heat Treatment – Bright Annealing or Conventional Annealing Furnaces ensure the tubes achieve the required mechanical properties and corrosion resistance. Precision Cutting & Sizing – The tubes are cut to required lengths with tight tolerances and smooth finishes. Quality Testing – Each tube undergoes rigorous testing including PMI, Hydrostatic, Eddy Current, Ultrasonic, and Dimensional Inspection to meet ASTM, ASME, and EN standards.

Product Size And Specifications

Products

Size & Range

Thickness

Specification

Instrumentation Tubes

3.00 mm to 25.40 mm OD

0.50 mm to 6.00 mm

ASTM A-213, A-269, A-789, EN 10216-5, SB-163, SB-167, SB-407, SB-423 & SB-444

U-Tubes as per Customers Drawing, Tubes can also be supplied as per AFNOR, GOST, JIS & EN Specification

TP-304/L/LN/H/N, TP-316/L/LN/H/N/Ti, TP-317L, 317LM, TP-321/H, TP-347/H, UNS S31050, S31254, UNS N08904, N08800, N08825, N08020, N08028, TP-405, TP-410, TP-430, TP-446, UNS S31260, S31500, S31803, S32304, S32205, S32750, S32760, UNS N04400, N06600, N06625, N06601&N010276

Available Grades

• High resistance to corrosion and oxidation.

•Smooth internal surface for efficient fluid and gas flow.

• Precision tolerances for seamless integration.

• Chemical Testing: Spectro Analysis, PMI Testing

• Mechanical Testing: Tensile, Hardness, Flaring & Flattening Tests

• Corrosion Testing: IGC Test

• Microstructure Testing: Grain Size Evaluation

• NDT Testing: Ultrasonic (UT), Eddy Current (ECT)

• PMI Testing: Verification of Material Composition