The Powerhouse Behind Every Pipe

Our modern manufacturing facility is equipped with cutting-edge technology and strict quality controls to deliver precision-engineered stainless steel seamless pipes and tubes. With efficiency, accuracy, and reliability at every step, we ensure world-class products for diverse industries.

Seamless Pipe & Tube - Manufacturing Process

Check Visual Dimensional

Billet Cutting

Heat Treatment

Received Raw MaterialWrite something...

Piercer ProcessCutting & Deburring

Straightening

Solution Annealing

Pickling Pipe Rolling

Sizing

Mother Hollow Inspection

Stretch Reducing

Cutting & Deburring

Straightening

Cooling

Solution Annealing

Lab Testing

Marking

Pickling

Eddy Current

Inspection

Hydro Testing

Check Inspection (Visual, PMI, UT, ECT)

Packing

Shipping

Dispatch

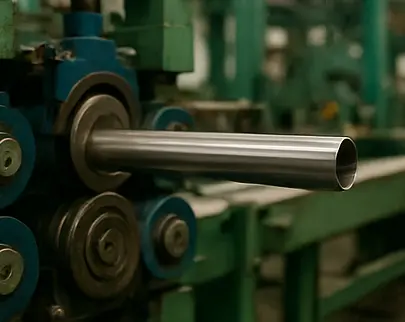

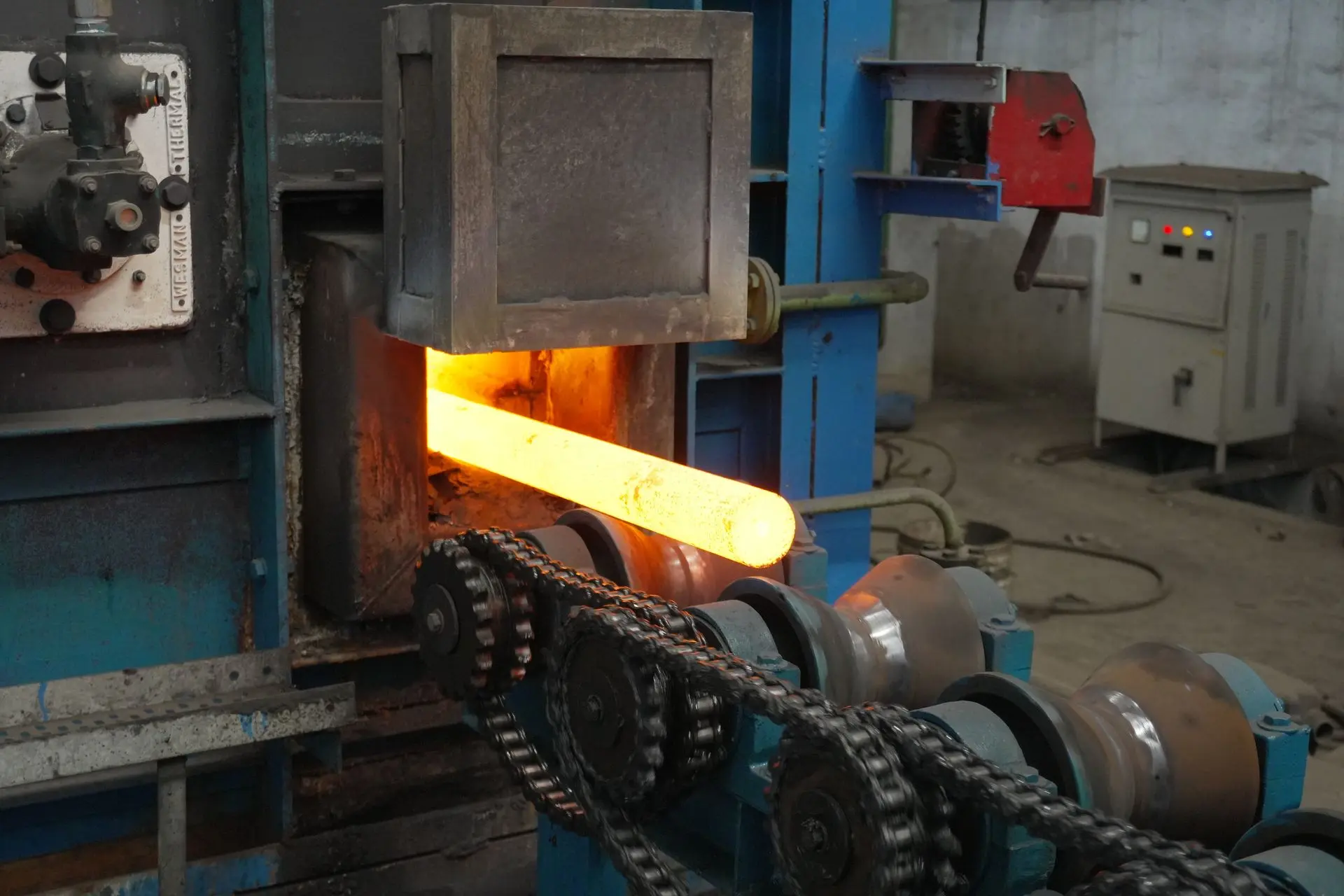

The hot piercing mill is a key process in the production of seamless pipes and tubes, enabling the transformation of solid steel billets into hollow tubes through a highly efficient and precise method. In this process, heated steel billets are driven through rotating rolls and pierced by a mandrel, creating a hollow shell. The piercing action, combined with extreme heat, allows the steel to be shaped into a seamless tube with uniform Simensions.

At Stancor Tubulars, our state-of-the-art hot piercing mills ensure exceptional dimensional accuracy and high strength in our seamless pipes. The intense heat during the process enhances the steel's metallurgical properties, making the pipes highly resistant to deformation and perfect for high-stress applications in industries like oil & gas, power generation, and petrochemicals.

The hot piercing mill also plays a crucial role in achieving the desired wall thickness and surface finish, ensuring that our seamless pipes meet the most rigorous industry standards. With this technology, STPPL is able to deliver high-quality, durable pipes that perform reliably in extreme environments while maintaining efficiency and precisioninproduction.

Precision Piercing & Tube Formation

-> The hot piercing process transforms a solid steel billet into a hollow tube through a combination of high pressure, rotation, and heat.

-> The billet passes through angled contoured rolls, which exert controlled tensile force, leading to the formation of a uniform cylindrical shell.

-> A water-cooled piercing mandrel is introduced, ensuring dimensional consistency while preventing structural flaws or deformations.

-> This procedure elongates the billet by up to twice its original length, while simultaneously refining its cross-sectional thickness by 33-50%.

Metallurgical Refinement & Structural Optimization

-> The precise engineering of the piercer point facilitates smooth metal flow, ensuring a homogeneous grain structure and eliminating internal irregularities.

-> If required, the pipes undergo a secondary pilgering process, further improving mechanical properties, external smoothness, and exact dimensional tolerances.

Heat Treatment & Rigorous Quality Validation

To ensure maximum durability, reliability, and performance in extreme conditions, our seamless pipes undergo:

-> Heat processing to enhance tensile strength and hardness.

-> Non-destructive testing (NDT) for flaw detection in both surface and subsurface layers.

-> Dimensional verification & ultrasonic analysis to comply with international regulatory standards.

-> Chemical treatment & finishing to improve corrosion resistance and longevity

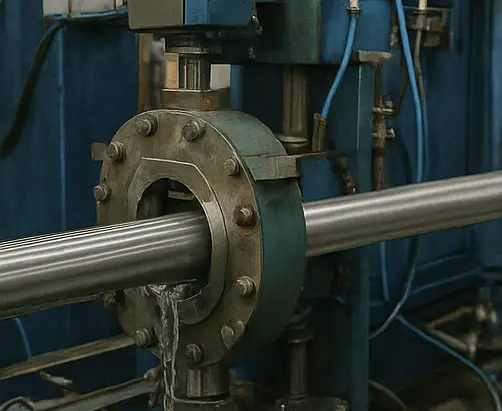

Heat Treatment Process – Enhancing Strength & Durability

At Stancor Tubular Products Pvt. Ltd., we employ advanced heat treatment processes to enhance the mechanical properties, durability, and corrosion resistance of our stainless steel pipes. Heat treatment is a crucial step in our manufacturing process, ensuring that our seamless pipes meet the highest industry standards for strength, ductility, and metallurgical uniformity.

Key Heat Treatment Processes:

• Solution Annealing: Stainless steel pipes are heated to a specific temperature and then rapidly cooled to relieve internal stresses, improve corrosion resistance, and restore ductility.

• Normalizing: Pipes are heated above the transformation range and air-cooled to refine grain structure and enhance mechanical properties.

• Stress Relieving: Used to reduce residual stresses from manufacturing, improving stability and dimensional accuracy.

Benefits of Heat Treatment at Stancor Tubulars:

• Enhanced strength and toughness for demanding applications.

• Improved corrosion resistance for harsh environments.

• Optimized grain structure for superior performance.

• Uniform mechanical properties across all pipes.

With state-of-the-art furnaces and strict process control, Stancor Tubulars ensures that every heat-treated stainless-steel pipe meets international quality standards, making them ideal for oil & gas, petrochemical, power, and industrial applications.

Write something...

Write something...

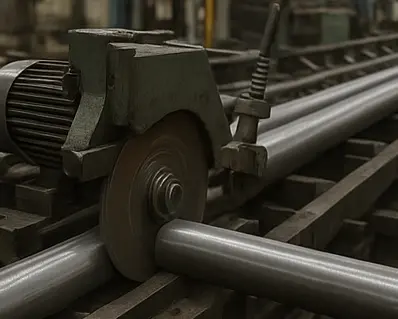

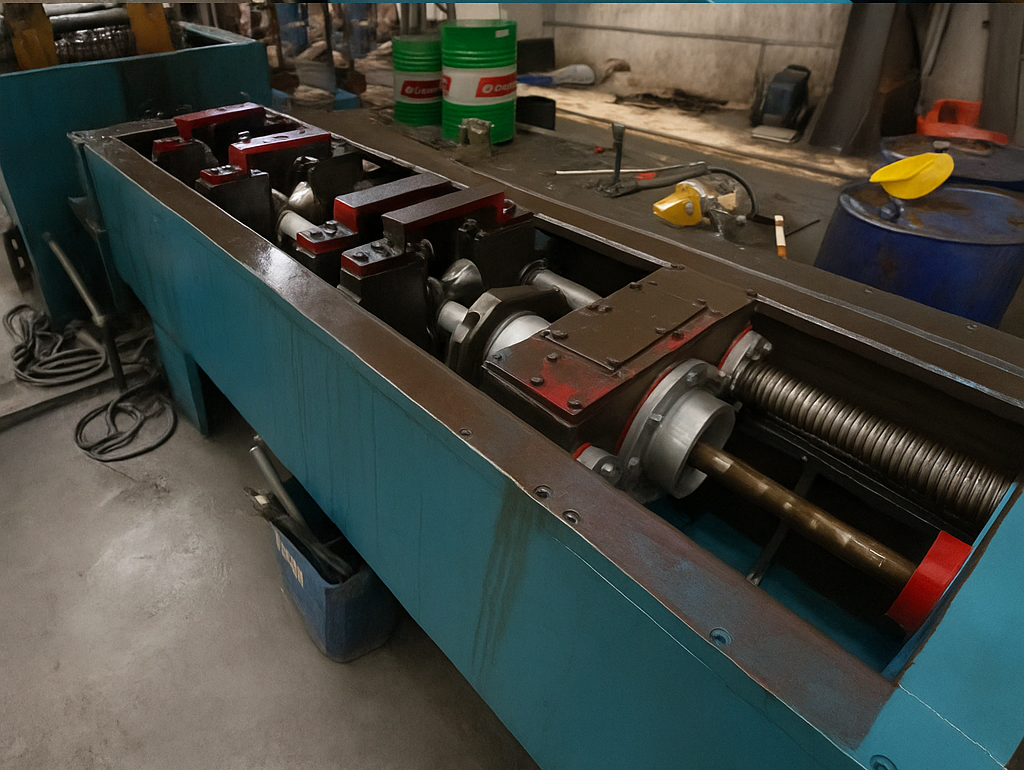

The pilgering process is a critical method in the manufacturing of seamless pipes and tubes, known for producing high-precision tubes with superior surface finishes. At Stancor Tubulars, we utilize cold pilgering, a technique that reduces the diameter and wall thickness of pipes through a series of highly controlled mechanical steps. This process involves passing a hollow metal tube between two rollers, which apply extreme pressure while simultaneously rotating, reducing the tube's dimensions.

Pilgering ensures tighter tolerances and uniformity in wall thickness, resulting in a product that meets the demanding specifications of industries such as oil & gas, petrochemical, and aerospace. It significantly improves the mechanical properties of the tube, enhancing its strength, durability, and resistance to high-pressure environments. Additionally, our advanced pilgering techniques allow us to achieve high precision in seamless pipe manufacturing, with minimal material waste, ensuring both efficiency and sustainability in our production process.

This method positions Stancor Tubulars at the forefront of seamless pipe and tube manufacturing, delivering superior quality that supports critical applications across diverseindustries.